What

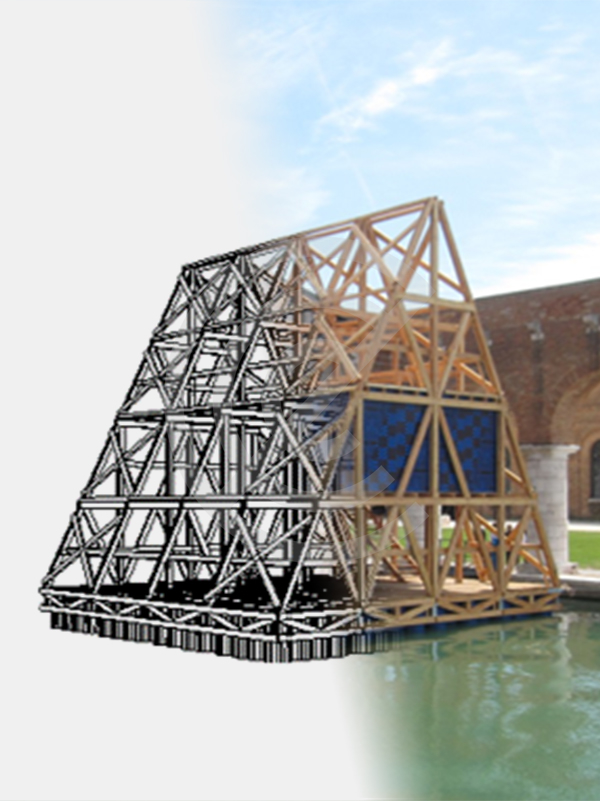

DfMA (Design for Manufactoring and Assembly) is a mix of things: It includes static, production, assembly, and loading drawings, as well as a feasibility study and value engineering as per the holistic design approach. DfMA is a complete change to the traditional sequence of the design: Instead of “Design > Production > Site” it focuses on “Production and Logistics > Site > Design”. In this way, the design is driven by production. Buildability. At Ergodomus we know very well that working in a DfMA workflow is not easy: even a little mistake can be very expensive and the chain-of-command and workflows are clear, so the audit trail quickly leads to the responsible party if there is a mistake. Nevertheless, we believe that off-site construction is the future, and that this is therefore the only way to engineer timber structures!

Once our scope of work is complete, we’re sure that all the elements can be produced, pre-assembled, transported and installed on-site. We know how the elements are manufactured and machined with a CNC robot, and we know how they are transported, and we know how they are assembled. We are constantly in communication with all stakeholders in the value chain.

For this reason, we work for many international CLT/GLT manufacturers, developers and builders. We also believe that the DfMA service can be very useful for architects.

More details

Ergodomus has been operating within these workflows for over 15 years and has developed many workflows that allow us to work with all the CLT/GLT manufacturers. We fully understand how complex these operations are and how expensive any errors can be: an error in our 3D drawing will be reported by the CNC machine, which by its nature is precision instrument, but "mindless" as it simply executes the sequence of commands sent via the electronic cutting tickets.

For this reason, we work with various manufacturers as "bespoke tailors", preparing workflows and files "tailor-made" on the specific needs of each company. No matter what the complexity of the project or the cutting machine is. We can communicate to almost any machine. SCM, Hundegger, Esse3, Biesse, Kuka, ABB, etc. Contact us to see what we can do for you!

Don’t believe it? Check our portfolio and contact us! We'll show you how we can help you, no matter the complexity and the size of the project.

Why ?

Ergodomus offers a unique skill of its kind: the ability to combine DfMA and structural analysis in one single company. In this way, no data is lost and a very well tested lean workflow allows us to optimize members’ size and CNC machining.

Sub services

Nesting

This is a very important process, which reduces the waste of CLT. A good nesting algorithm must fill all the empty spaces (including those of the openings) and take into account the orientation of the CLT grain.

CNC & Robot pre-fab

The MMC (Modern Methods of Construction) can not ignore robotics. Ergodomus helps you by programming your specific robot model to obtain perfect dimensioning of your material translating between design and machined elements.

Off-site

Pre-fabrication reduces the time on-site, improving the quality, and reducing installation errors on the construction site. There are many examples of this, such as ribbed insulated floors, LVL floor cassettes, and timber framed walls etc…

Computational Design

This is the current and the future of design. It allows you to easily manage the design and manufacture of complex shapes, to automate repetitive tasks, and to compare a myriad of different solutions with each other.

Read more