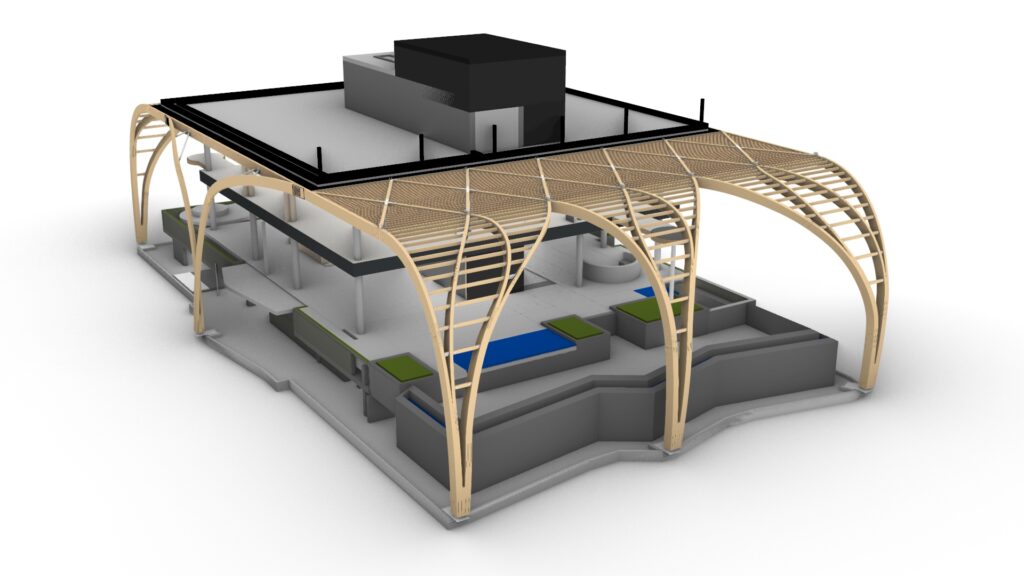

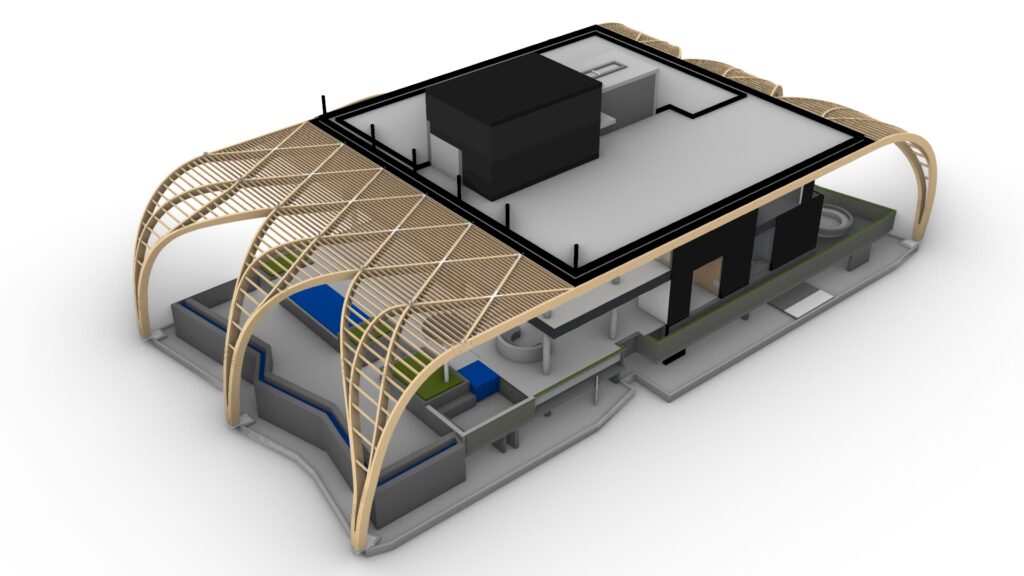

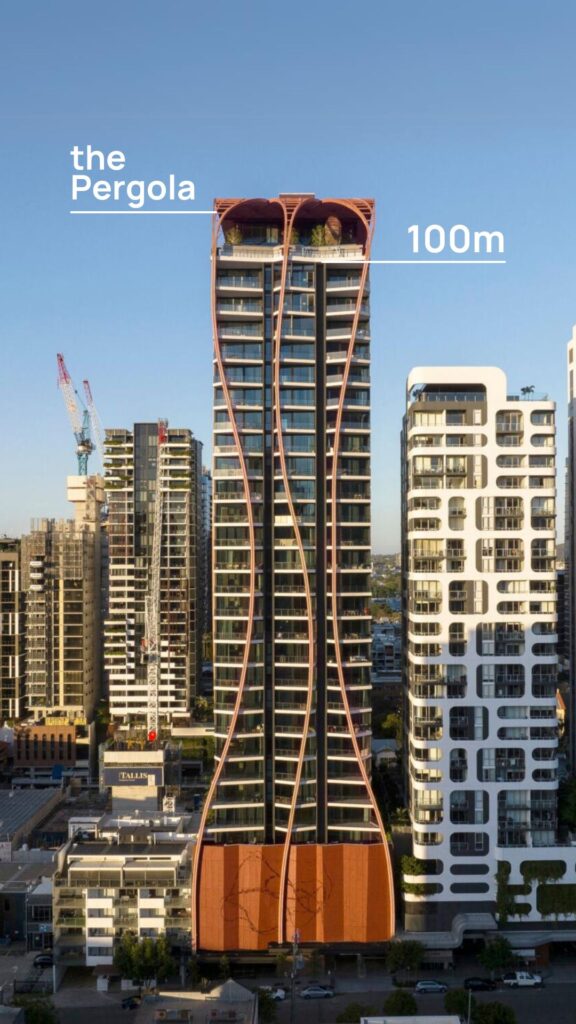

In the heart of Brisbane, Australia, the Upper House stands as a new icon of architectural innovation and sustainable design. Conceived by Koichi Takada Architects, this extraordinary structure draws inspiration from the lush forms of the Daintree Rainforest, seamlessly blending nature with urban living. Atop this skyscraper, over 100 meters above street level, a breathtaking panoramic pergola graces the skyline—a testament to innovation, precision, and the possibilities of modern timber engineering.

A Fusion of Nature and Architecture by Koichi Takada Architects

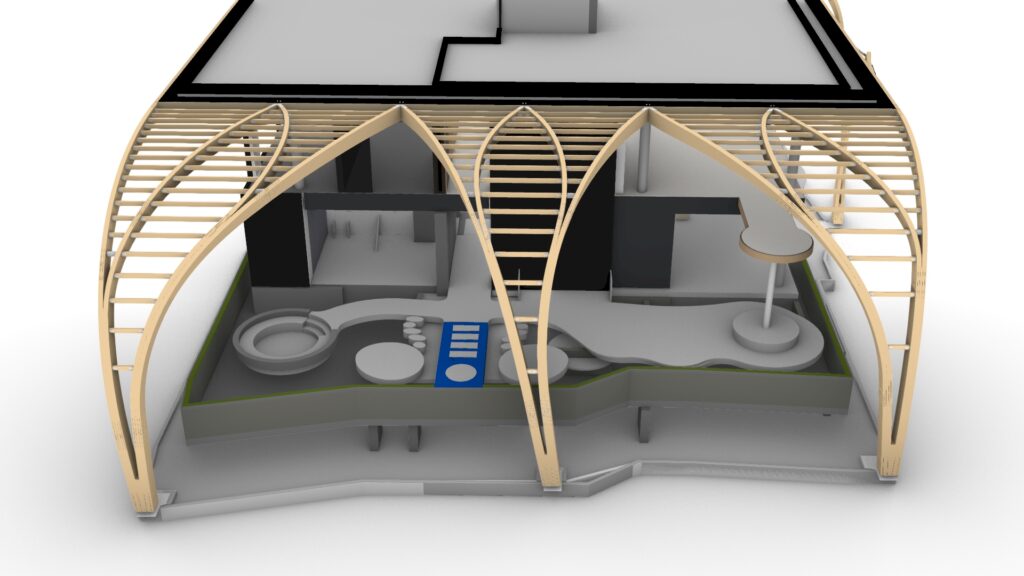

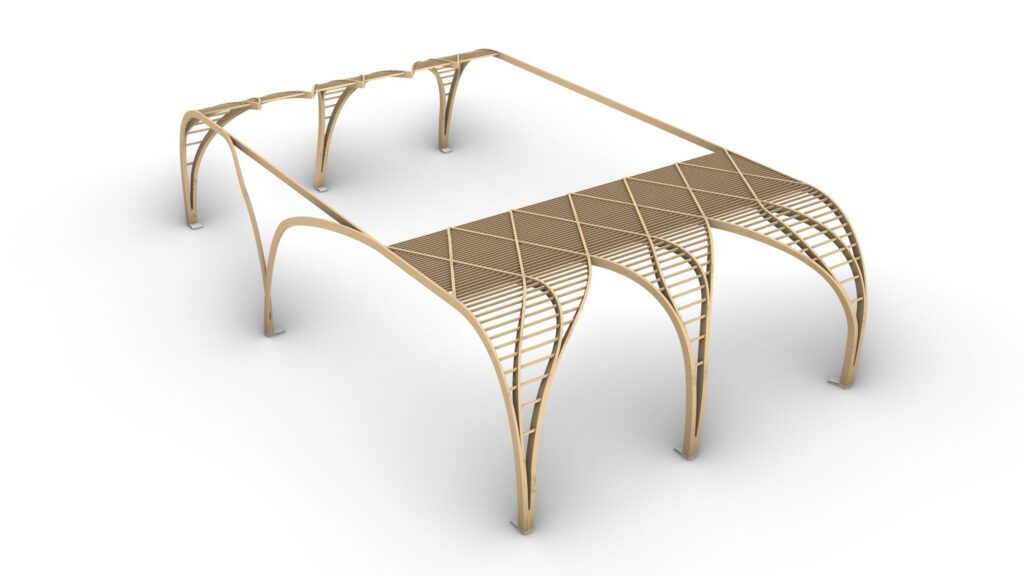

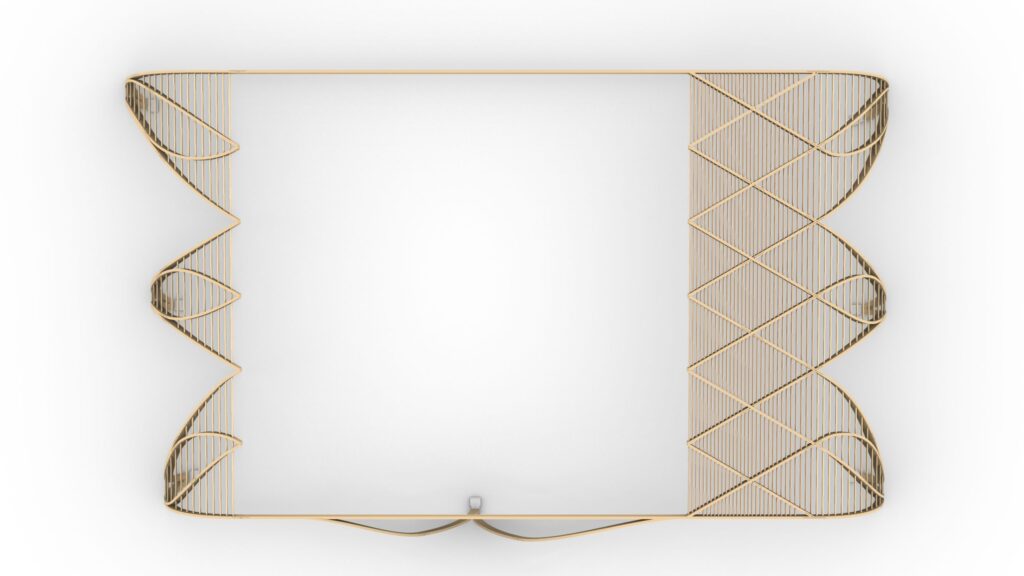

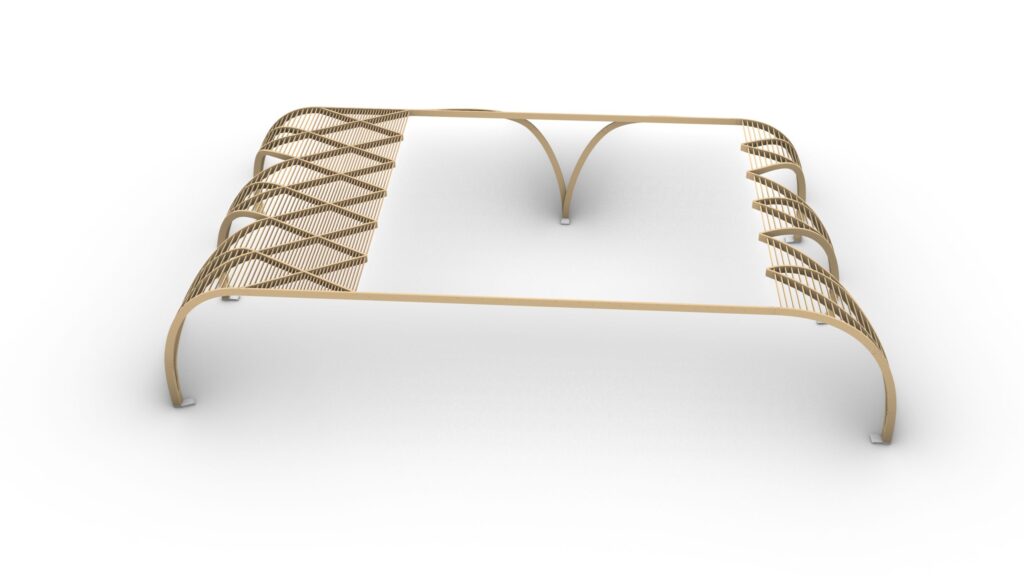

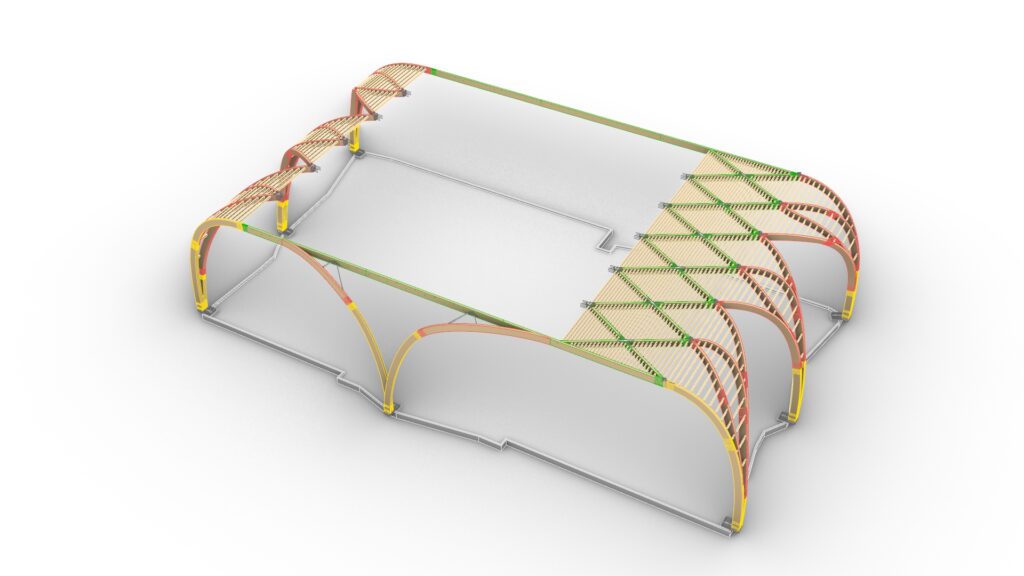

Koichi Takada Architects envisioned the Upper House as a harmonious integration of natural elements within an urban context. The rooftop pergola, with its intricate double-curved timber beams and expansive 1,000 m² leisure area, offers residents a serene escape amidst the bustling cityscape. The design reflects the firm’s commitment to creating spaces that connect people with nature, enhancing well-being and fostering a sense of community.

Off-Site Excellence and DfMA Approach

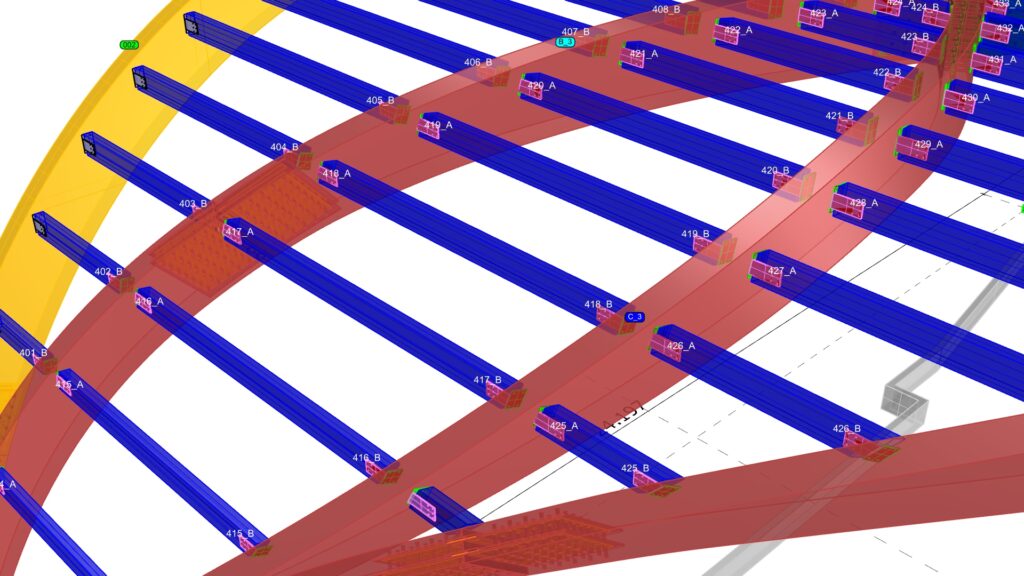

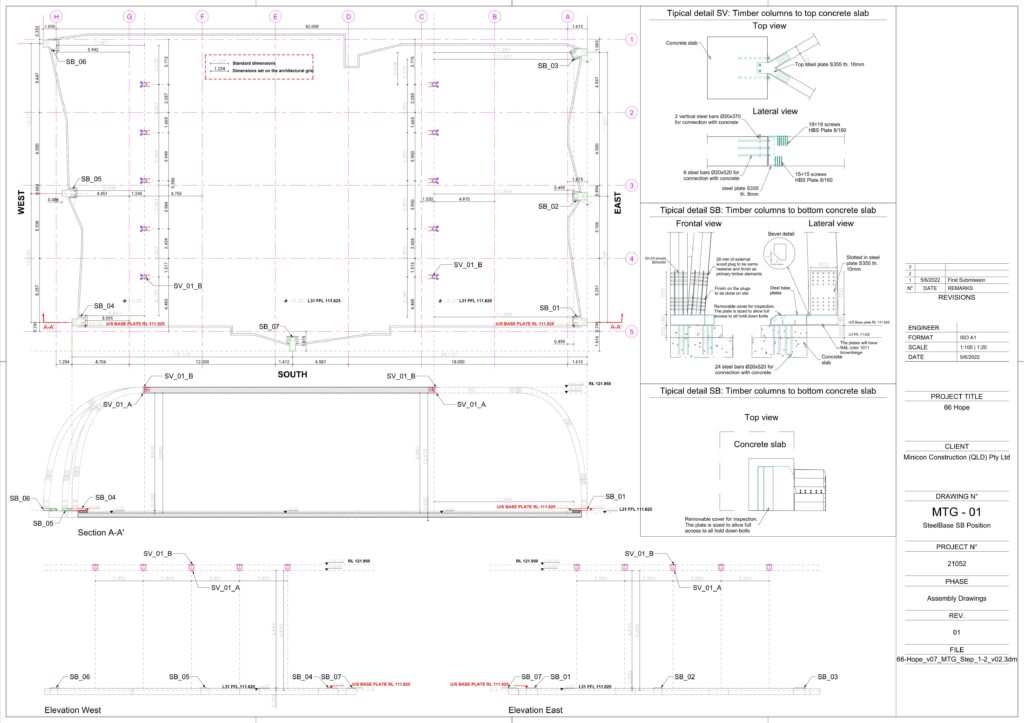

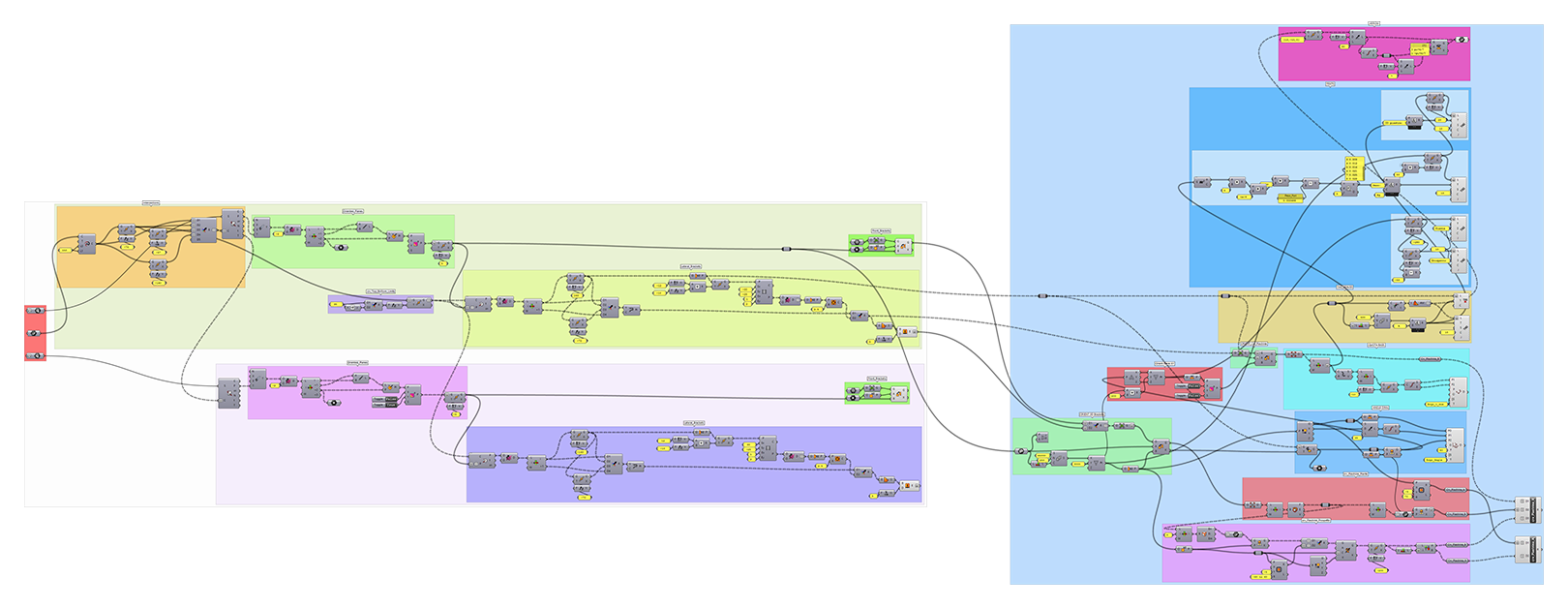

The realization of this architectural masterpiece was made possible through the collaborative efforts of Ergodomus Timber Engineering and Koichi Takada Architects. Embracing the Design for Manufacture and Assembly (DfMA) methodology, coupled with the WYDIWYG (“What You DRAW Is What You Get”) approach, we ensured that the architect’s visionary design was translated accurately into reality. Recognizing the importance of off-site construction for a project of this complexity, we developed a comprehensive digital 3D model that served as a single source of truth, facilitating seamless collaboration and precision from conception to assembly.

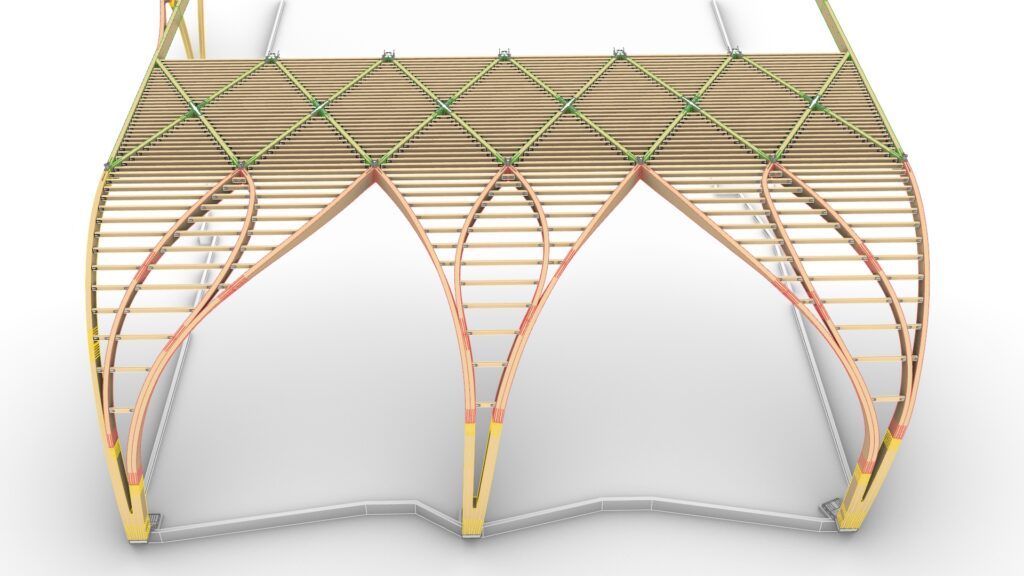

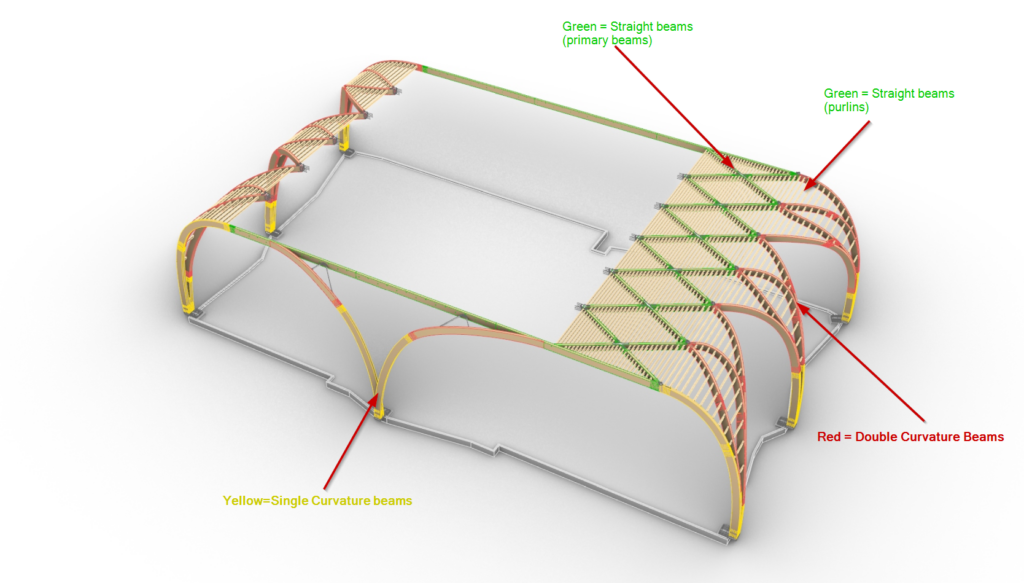

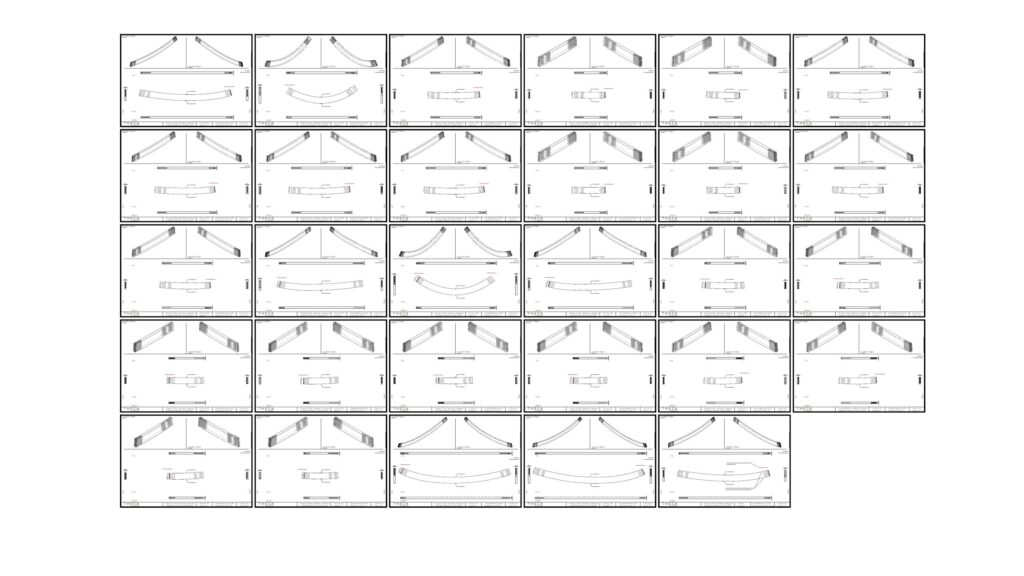

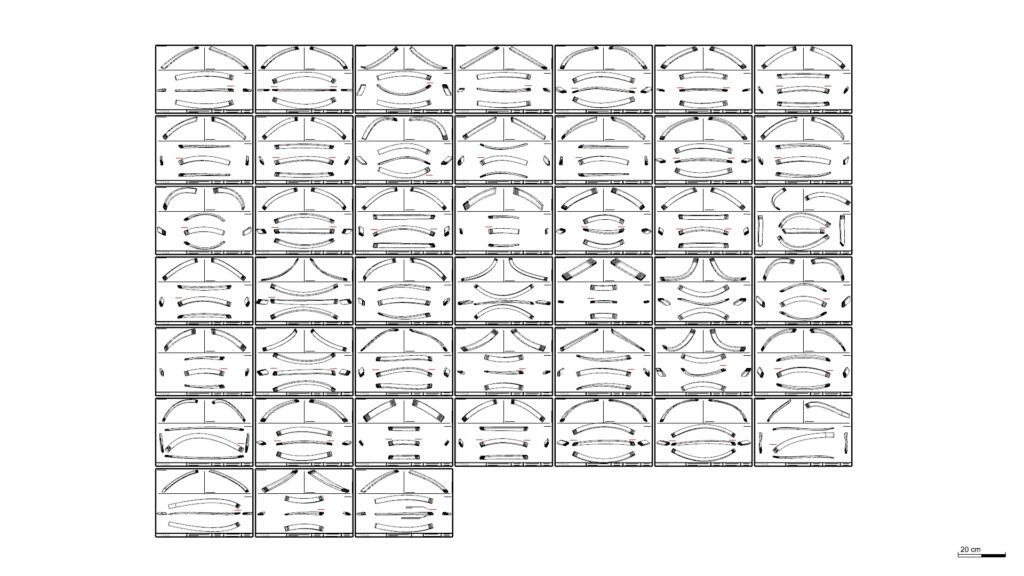

Parametric Design and Double-Curved Timber Elements

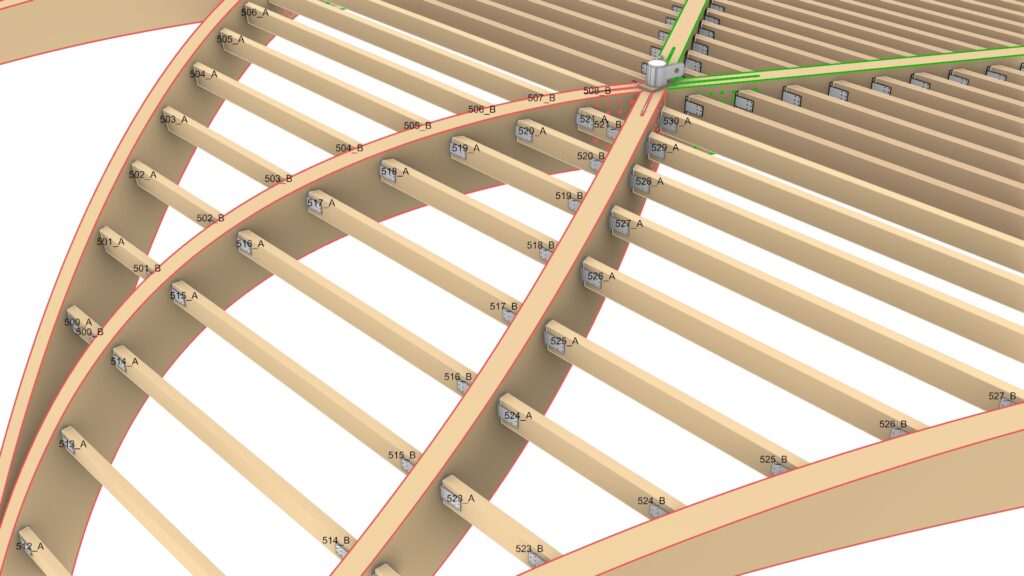

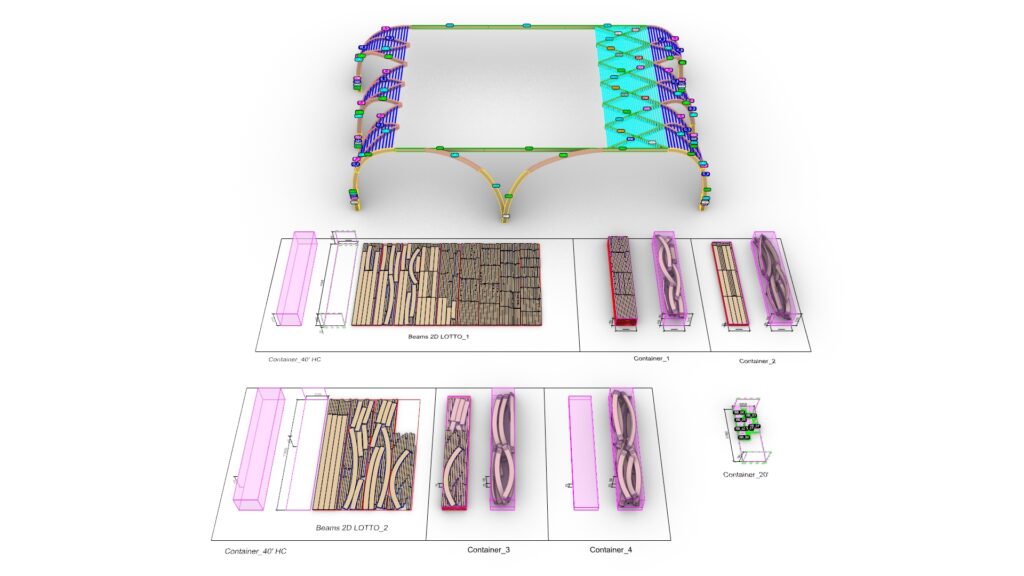

A standout feature of the Upper House pergola is the incorporation of double-curved timber elements. This is an exceptional and intricate aspect of timber construction. These elements required advanced parametric design techniques. We utilized tools like Rhinoceros and Grasshopper, to achieve the complex geometries envisioned by the architects. The structure comprises:

- 44 double-curved beams

- 28 single-curved beams

- 26 straight beams

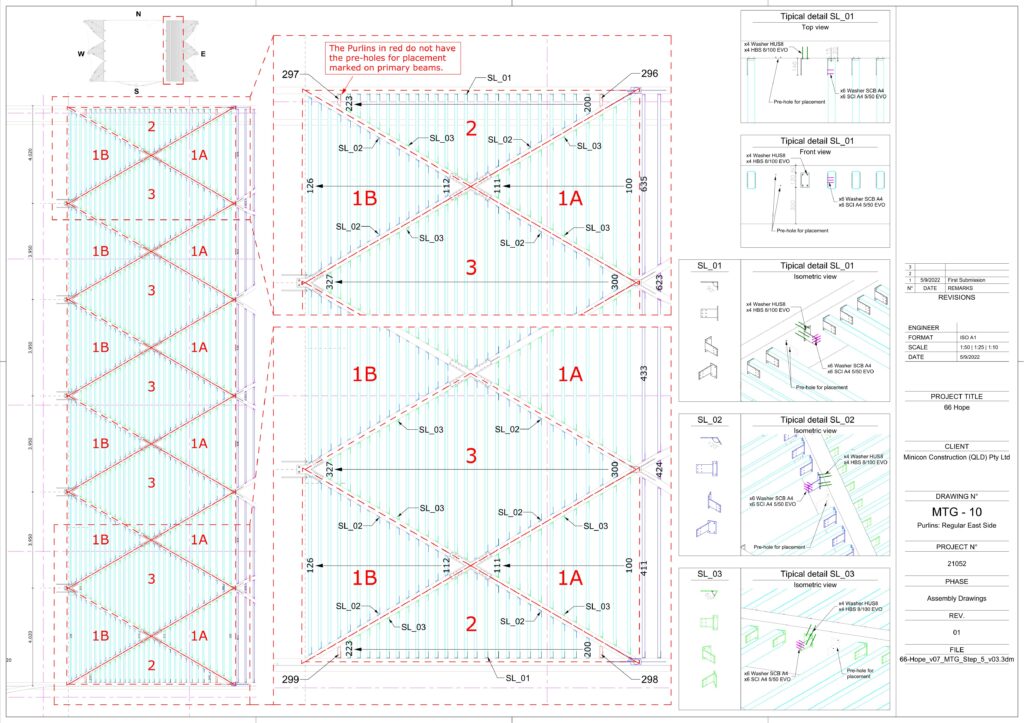

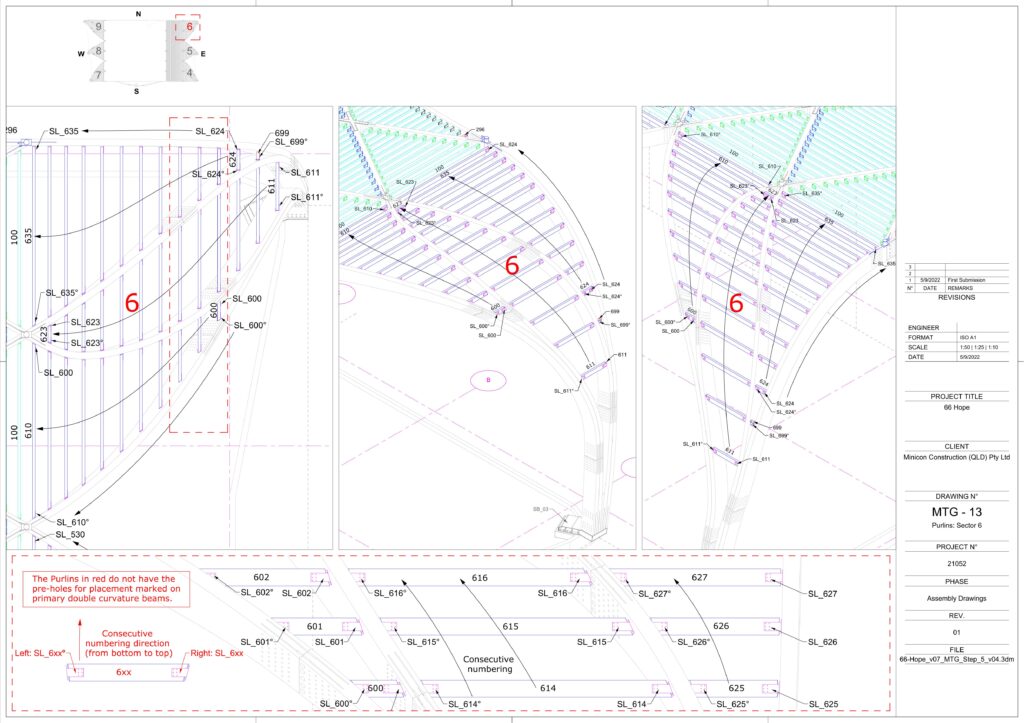

- 573 purlins, with 219 varying in length and cutting angles

Each primary beam, with a cross-section of 140×480 mm and lengths ranging from 5 to 8 meters, was meticulously engineered to meet both structural and aesthetic demands.

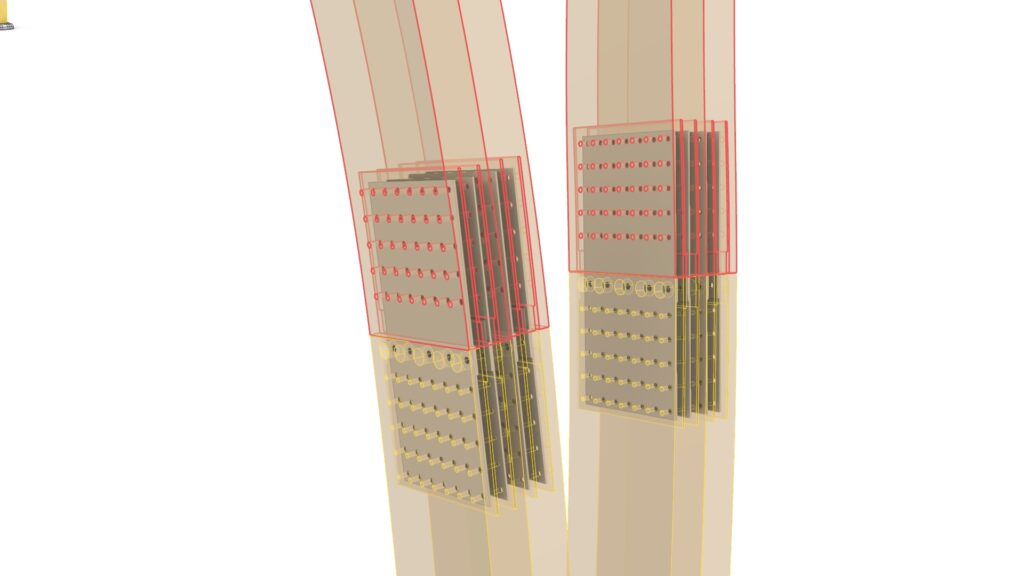

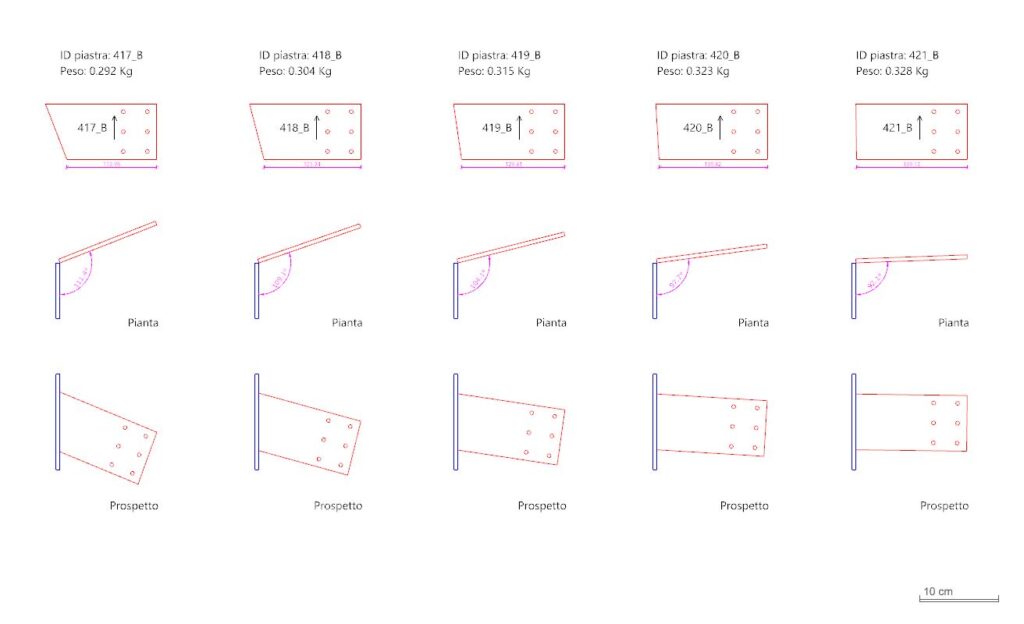

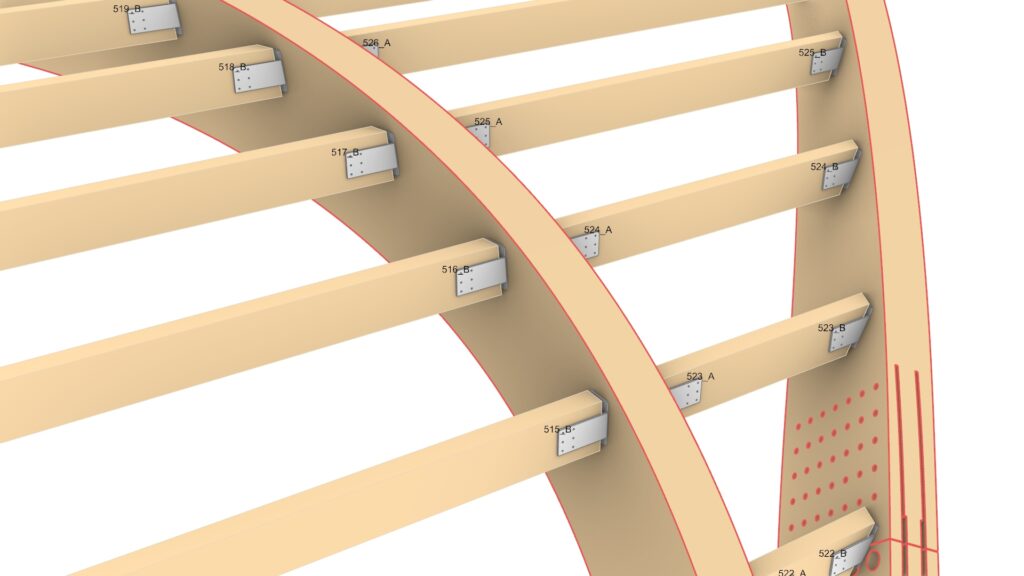

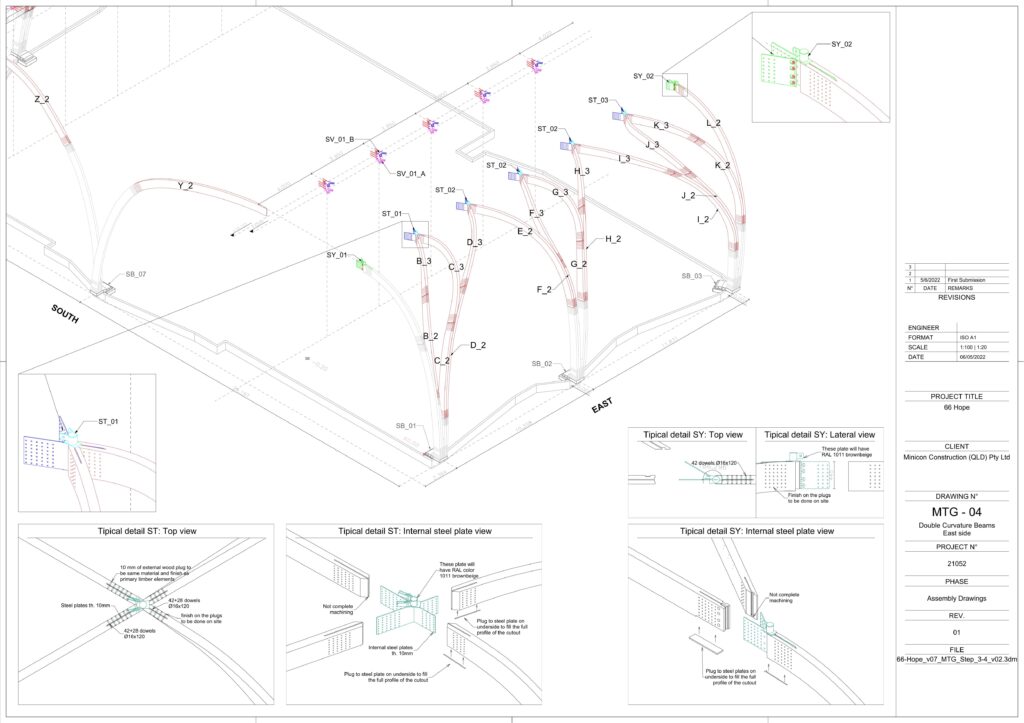

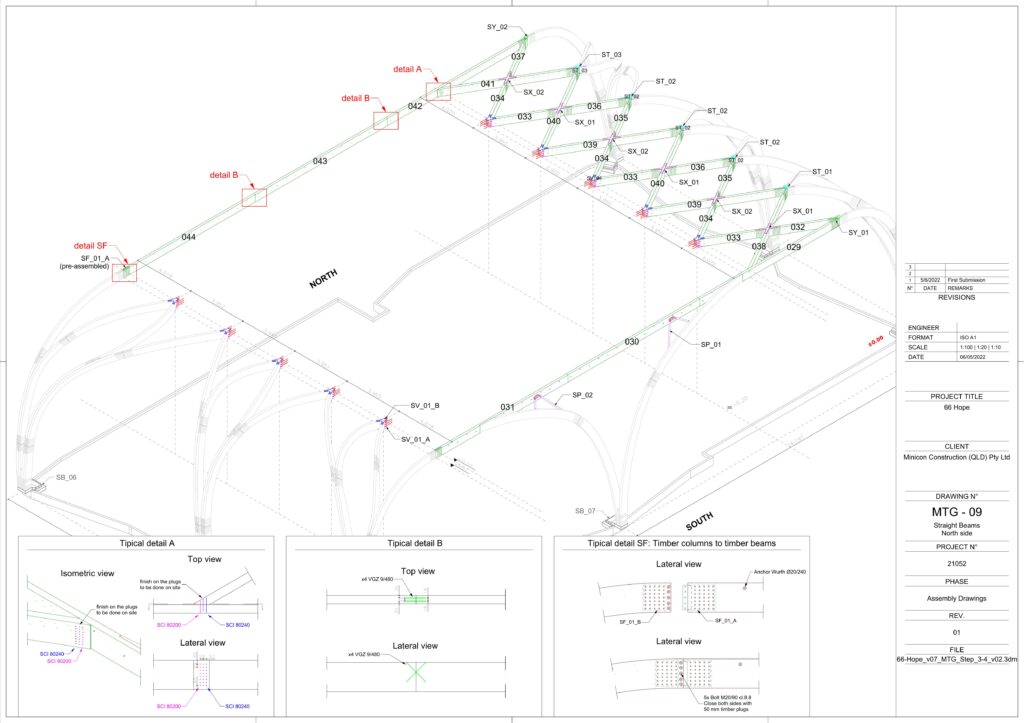

Mastering Complex Connections with Precision

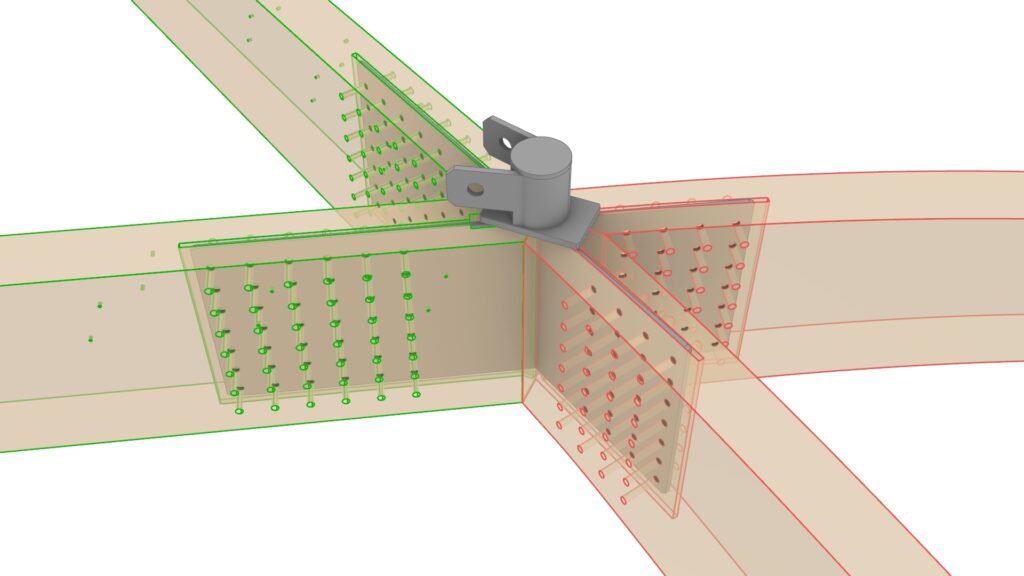

Connecting the double-curved beams to the single-curved columns presented significant engineering challenges. To achieve the seamless intersections and dynamic forms desired by Koichi Takada Architects, meticulous attention was given to the design and orientation of steel plates and milling for connections. Innovative solutions, such as creating guide holes, facilitated precise on-site assembly despite the inherent difficulties of working with double-curved elements at great heights.

We engineered hundreds of custom steel connections, each uniquely identified to streamline the assembly process. This level of customization ensured perfect alignment and structural integrity, essential for the safety and longevity of the pergola.

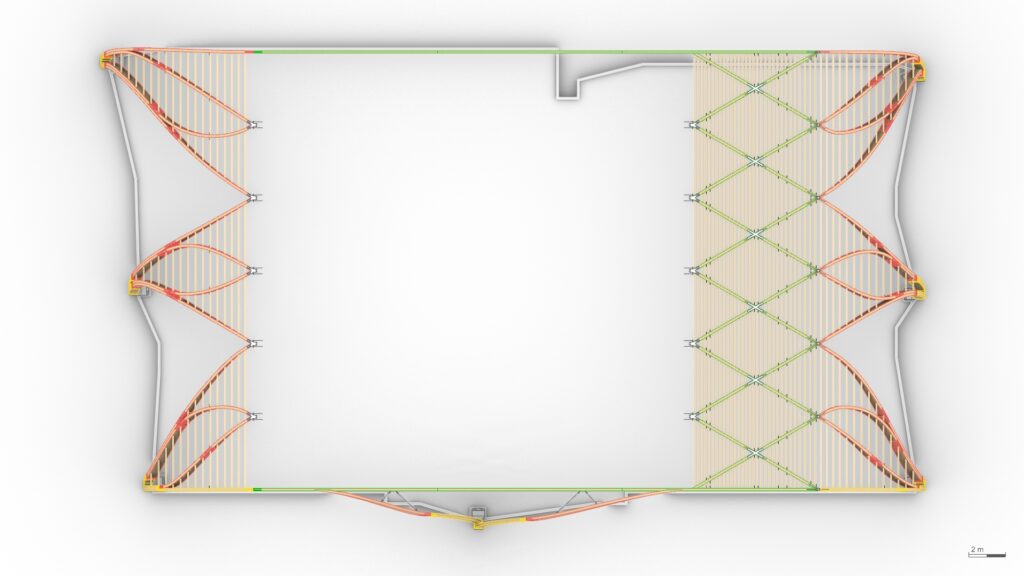

Collaborative Coordination and Unified Digital Model

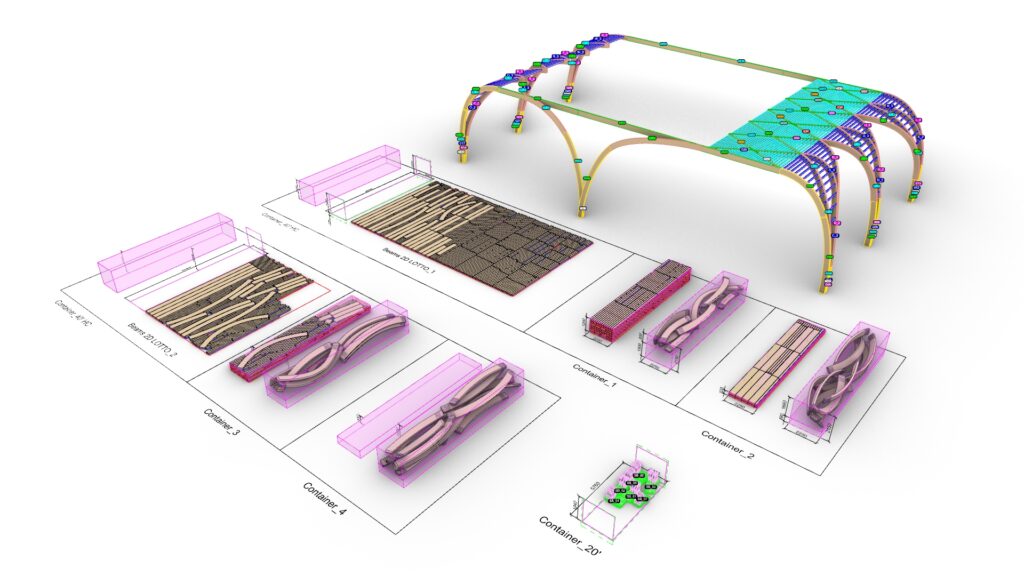

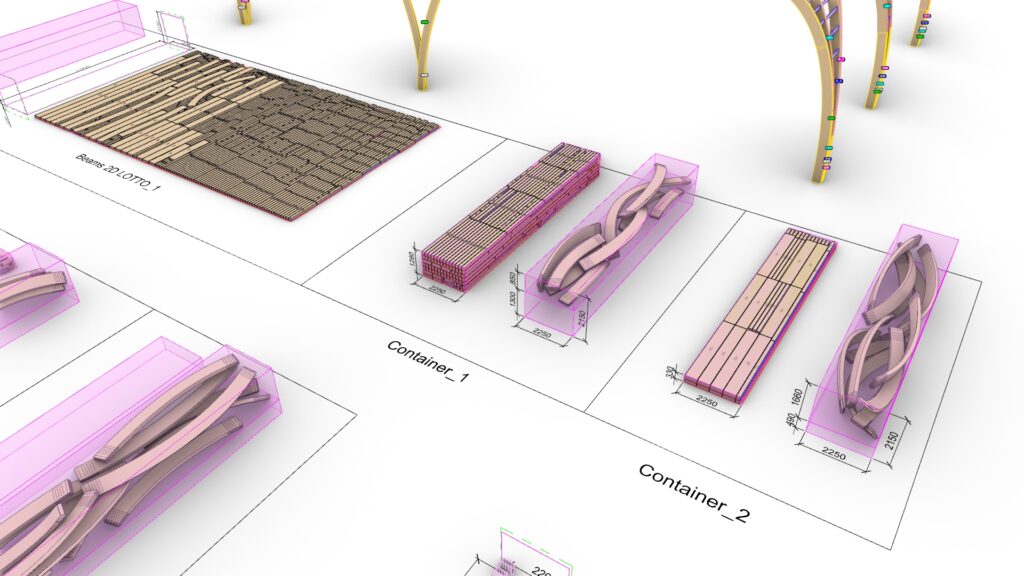

The project’s success hinged on the close collaboration between Ergodomus, Koichi Takada Architects, and various suppliers. We coordinated among three different suppliers:

- Steel components

- Single-curved and straight beams

- Double-curved beams

We used a unified digital 3D model to seamlessly integrate all components, ensuring we fully realized the architect’s vision. Our team prepared detailed assembly drawings and generated CNC files for manufacturing. Our engineers and drafters strictly adhered to the WYDIWYG principle to maintain fidelity between design and execution.

Look at the 3D Digital Model we made

We shared this Digital Model via Speckle

On-Site Precision and Integration

An exact survey of the concrete sub-structure was conducted to guarantee perfect integration of the timber elements with the existing building. This precision was crucial, given the project’s complexity and the challenges associated with assembling such a structure over 100 meters above ground.

Innovation Through DfMA(d) and Quality Assurance

Employing our DfMA(d) approach—Design for Manufacture, Assembly, and Disassembly—we optimized the construction process and considered future adaptability. Multiple visits to production sites ensured rigorous quality control, verifying that all components met our stringent standards before shipment. Our comprehensive involvement, from digital modeling to production oversight, exemplified our commitment to excellence.

Overcoming Logistical Challenges

Transporting large, complex components from Italy to Australia posed significant logistical challenges. Through meticulous planning, we developed an extensive loading plan, optimizing the nesting and positioning of curved beams and steel plates within shipping containers. This effort minimized the number of containers required, reduced assembly time on-site, and embodied the principles of Value Engineering.

A Harmonious Blend of Vision and Expertise

The Upper House pergola is a shining example of what can be achieved when architectural vision meets engineering expertise. Koichi Takada Architects’ dedication to creating spaces that resonate with natural beauty was matched by Ergodomus’s ability to solve complex engineering challenges. Together, we brought to life a structure that not only enhances Brisbane’s skyline but also provides residents with a tranquil, nature-inspired sanctuary.

This project underscores the transformative power of collaboration and innovation in modern construction. By integrating advanced computational design, off-site manufacturing, and meticulous project management, we overcame significant challenges. This way the structure was both aesthetically stunning and structurally sound. The Upper House pergola is a testament to the possibilities of timber engineering and the profound impact of thoughtful design.