Practical strategies to match timber budgets with steel and concrete—without sacrificing sustainability or speed.

The True Cost Challenge of Mass Timber Buildings – Time Matters

Drawing on 20+ years at the forefront of the Mass Timber Era—from early CLT innovators to today’s groundbreaking global projects—this article is rooted in real‑world expertise. We’ve navigated complex building codes, managed projects of every scale, and spent countless nights resolving structural analysis puzzles, logistics bottlenecks, connection design hurdles, and orchestrating DfMA workflows. We celebrate our successes—but also embrace lessons from less-successful ventures through a Kaizen‑inspired lean approach, continuously refining our methods. Together, these experiences paint a holistic picture of what truly drives—and what holds back—timber construction costs.

Cost remains the top obstacle in mass timber construction. The debate over “which material is most expensive—timber, steel, concrete, or masonry?” has persisted for years without a definitive winner. Variables like raw material rates, foundation requirements, specialized hardware, transport logistics, on-site labor costs, crane usage, and more each carry different weight depending on whether you’re a developer, builder, investor, or designer. For some stakeholders, speed to market makes all the difference; for others, a longer schedule is acceptable.

Rather than aim for a single verdict, let’s explore the right approach that drives timber costs down and positions it as a truly competitive choice. Engage Ergodomus and leverage our deep experience to set your project on the right path from day one.

Move Beyond “€-$/m³ of Timber”

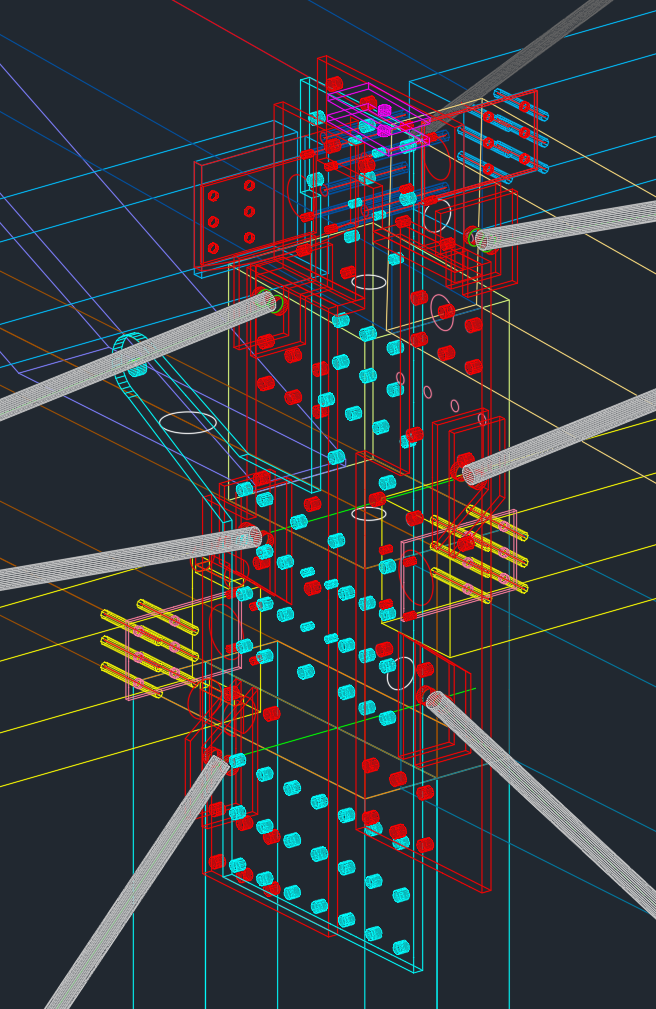

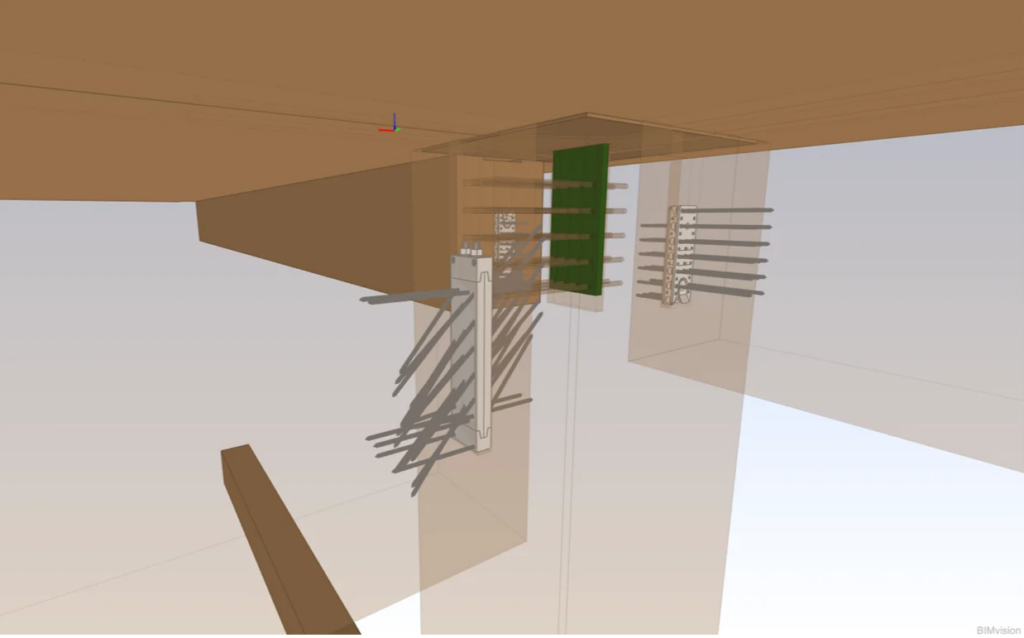

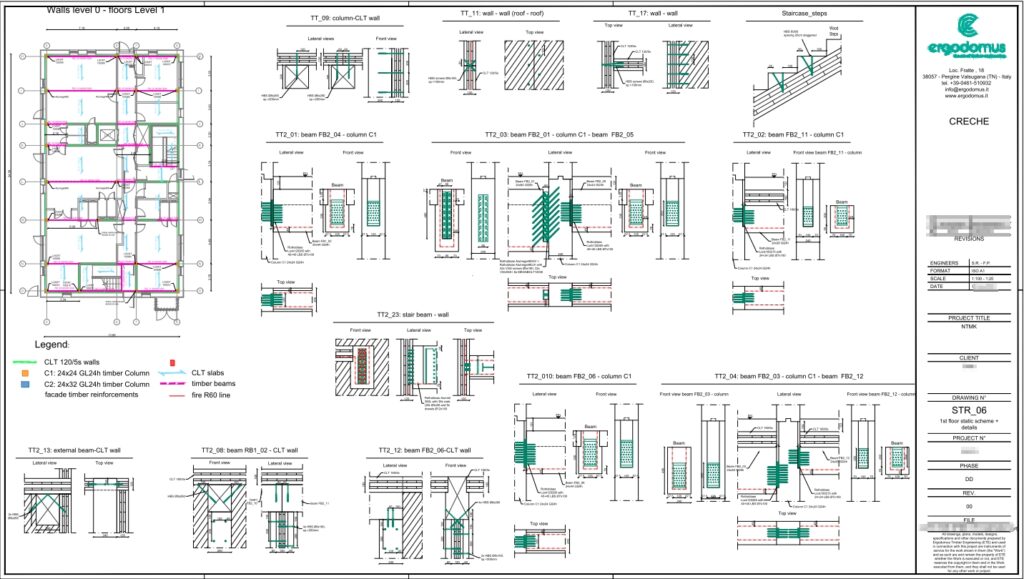

Comparing only the price per cubic meter of CLT, GLT, or LVL panels tells only part of the story. CLT panels typically range from 100–300 mm thick (3–9 plies), and GLT beam depths influence both structural capacity and aesthetic proportion. Cutting timber volume may seem like savings, but it often creates more complex joints, additional detailing, and higher crane or labor hours—erasing the benefit. To make good decisions, consider panelization, crane lifts, and on-site labor as part of your material cost.

Five Pillars of Cost Optimization

Driving down timber costs relies on five foundational pillars—ranked by impact and powered by a DfMA approach (Design for Manufacturing and Assembly):

1. Experience (XP)

Only experienced timber engineers spot hidden efficiencies. Beyond raw volume, a holistic lens evaluates logistics, supply‑chain coordination, on‑site vs. off‑site processes, acoustic requirements, structural analysis, connections and details, façade integration, sustainability targets, and each client’s goals. This breadth of knowledge comes from projects large and small, simple and complex—and from both successes and setbacks.

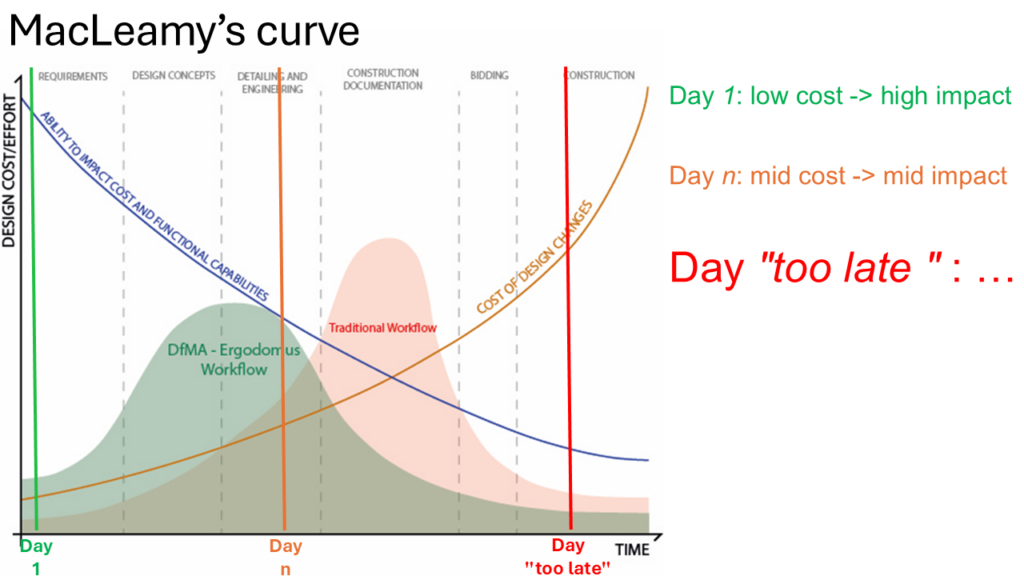

2. Early Expert Involvement

The McLeamy Curve shows the earlier you engage a Mass Timber Expert, the greater the opportunity to influence design, materials, and methods—and the deeper the cost savings. Yet developers, investors, and builders often bring us—or other specialists—in far too late, when redesigns are prohibitively expensive and permit changes carry high risk. Even if you could waive design fees, there’s no time to rework structural grids, tweak layouts, or refine details. Reapplying for permits introduces further delays, costs, and uncertainty. Suppose you accepted that risk and had time—who would shoulder the extra redesign cost?

3. Time – “Think Slow, Act Fast”

Only experienced timbIndustry data shows on-site unproductive time can reach 40–50%. An hour spent refining a detail in the office (cost unit = 1) can save roughly four hours in the field (cost unit = 4 for crew + crane). That 1:4 ratio follows Pareto’s rule—20% effort up front generates 80% savings on-site. But achieving that requires deep XP, thorough off-site pre‑assembly planning, and clear coordination.

4. Holistic Cost vs. Time Trade-Off

Real cost equals material expense + installation time. Consider three scenarios:

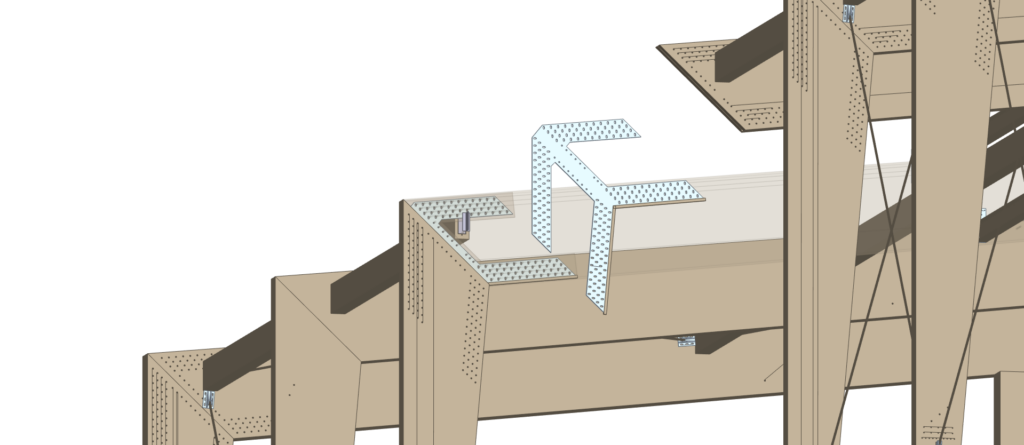

- Product A vs. B: A is 20% cheaper in hardware but takes 200% longer to install. B costs more per unit but installs swiftly. When labor and crane rates dominate, faster installation pays off.

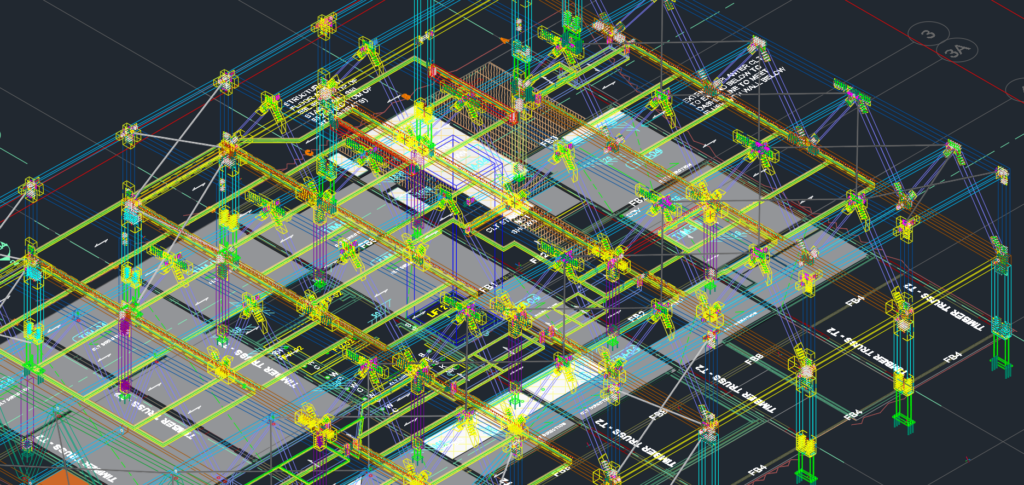

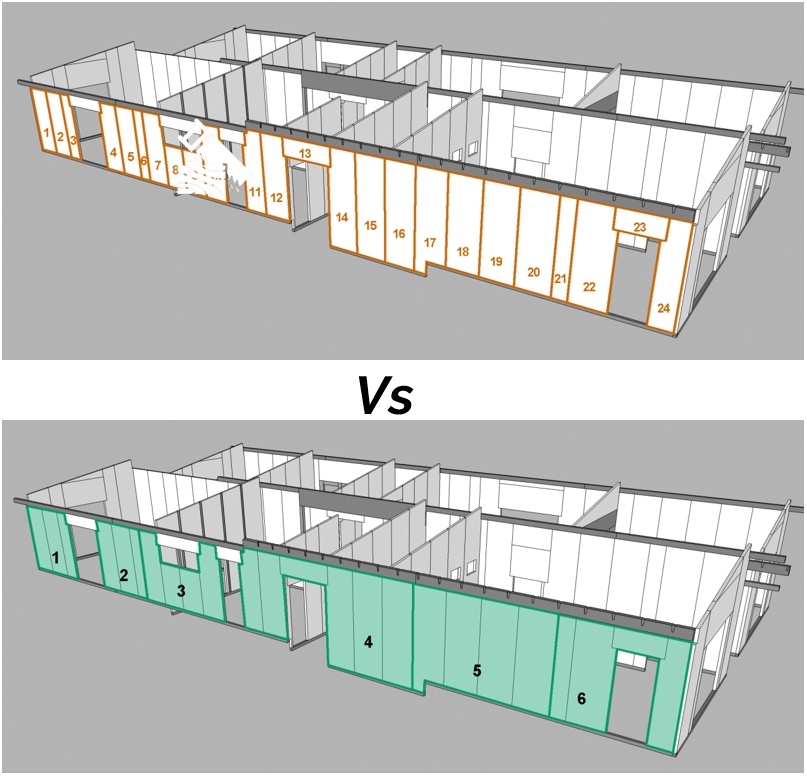

- Optimized CLT Layout: Reducing panel count streamlines crane operations, minimizes joints, and accelerates assembly.

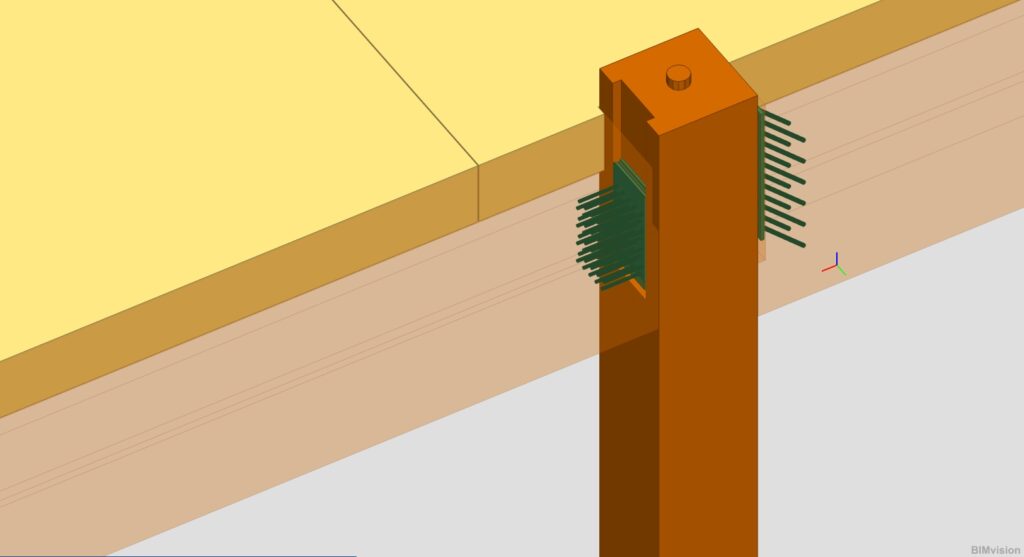

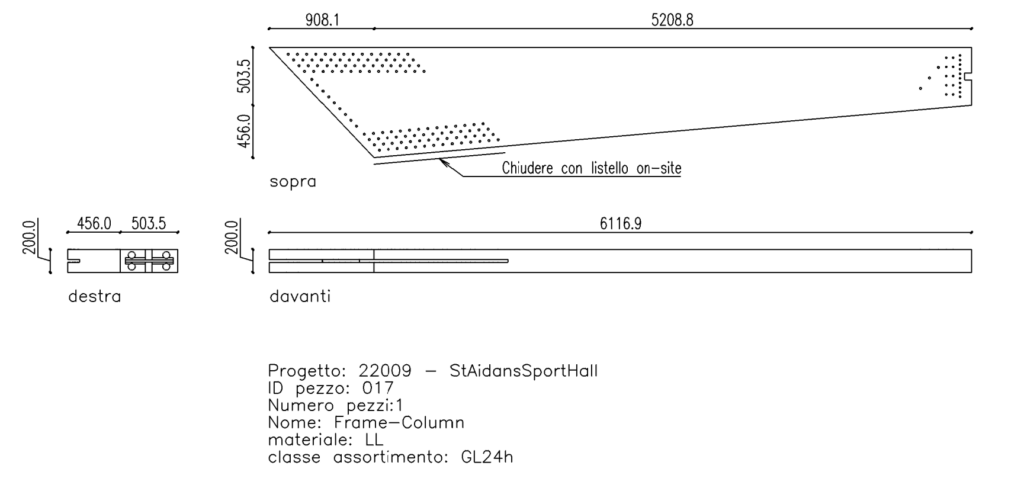

- Off‑site Pre‑assembly of Connections: Pre‑assembling connections halves field labor but demands planning for container capacity, protective packaging, and transport handling. A true DfMA approach integrates production, logistics, and assembly from square one.

5. Dedicated Timber Project Management

Effective PM in timber demands leaders with full‑cycle XP—from design through factory production, transport logistics, to on‑site assembly. They synchronize fabrication, BIM workflows, shop drawings, and all disciplines under one DfMA umbrella—no more chasing mismatched 2D PDFs. They maintain consistent pace across architects, MEP and structural engineers, and contractors—avoiding bottlenecks, missing data, or “gray areas” that stall progress. True PM is not about shouting for 36‑hour workdays; it’s about realistic schedules, off‑site pre‑assembly, and smooth coordination.

Introducing CPC & CPS Indices

To quantify true efficiency, we devised two metrics:

- CPC (m³ of timber per m³ of building)

- CPS (m³ of timber per m² of building)

Our aim? Minimize CPC and CPS to amplify timber’s competitiveness. Saved volume becomes CO₂ storage—or fuel for your next project.

I often see calls to add more timber purely for carbon storage. But bigger volumes spike costs, erode competitiveness, and frustrate clients—who then abandon timber. If budgets tighten, investors and developers pivot to cheaper frames, and timber use shrinks. Let’s face it: budgets drive decisions more than ideals. That’s why at Ergodomus we bridge cost efficiency and sustainability, serving your bottom line and the planet.

It’s time for Smart Timber, not just Mass Timber. And please not “Mess Timber“!

How Ergodomus can Help

With nearly 20 years of global timber engineering leadership, Ergodomus delivers:

- Early‑stage consulting & feasibility studies to get the right footing.

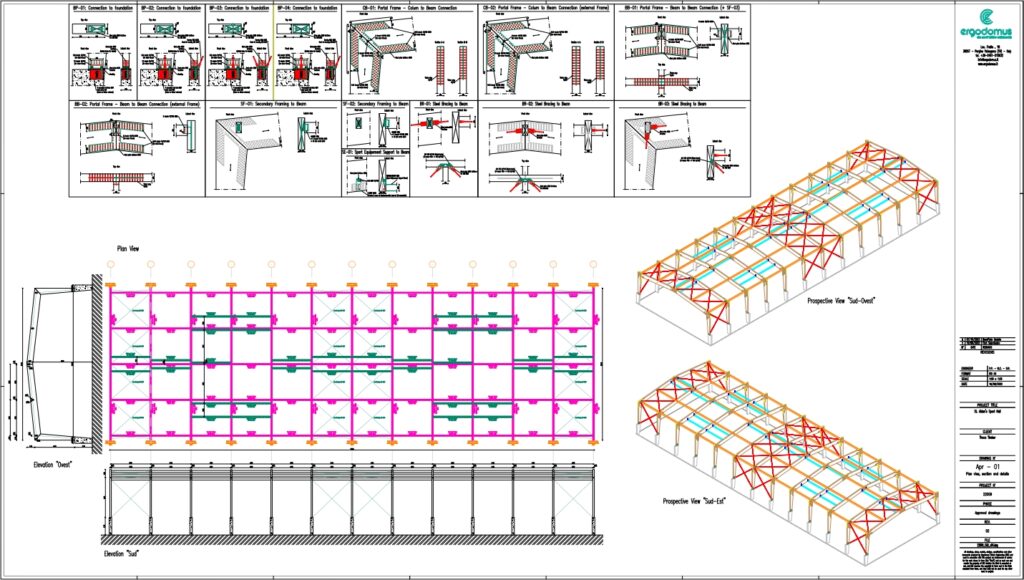

- Expert timber detailing services that simplify assembly and cut field hours.

- DfMA‑driven workflows integrating analysis, shop drawings, and logistics.

- Project management tailored for off‑site production and on‑site execution.

- Cost/benefit studies leveraging CPC and CPS insights.

Ready to get Started?

Partner with us to infuse creativity and technical mastery into every joint and panel. Let’s prove that timber can be both sustainable and cost‑effective.

Let’s Hear Your Thoughts

We want to hear your real‑world experiences. Share your insights on LinkedIn!

- Bring a success story! Tell us about a mass‑timber project that stayed on budget—what decisions or tactics made it shine?

- When costs killed timber: Have you watched a project pivot to concrete or steel because timber pricing spiraled? What tipped the scales?

- Five‑Pillar check‑in: Do our pillars—Experience, Early Involvement, Time, Holistic Trade‑Offs, Project Management—feel right? Would you reorder them, add one, or remove one?

- Expert timing: If a timber specialist arrived late on a past job, how did that affect redesign effort, permits, or schedules?

- Off‑site lessons: For teams that pre‑assembled connections, what logistics hurdles (packaging, transport, site handling) surprised you—and would you use the strategy again?

Drop a comment on LinkedIn here or share this article with a colleague who’s exploring timber buildings.