Bringing Parametric Design to Reality: The Parametric Wall

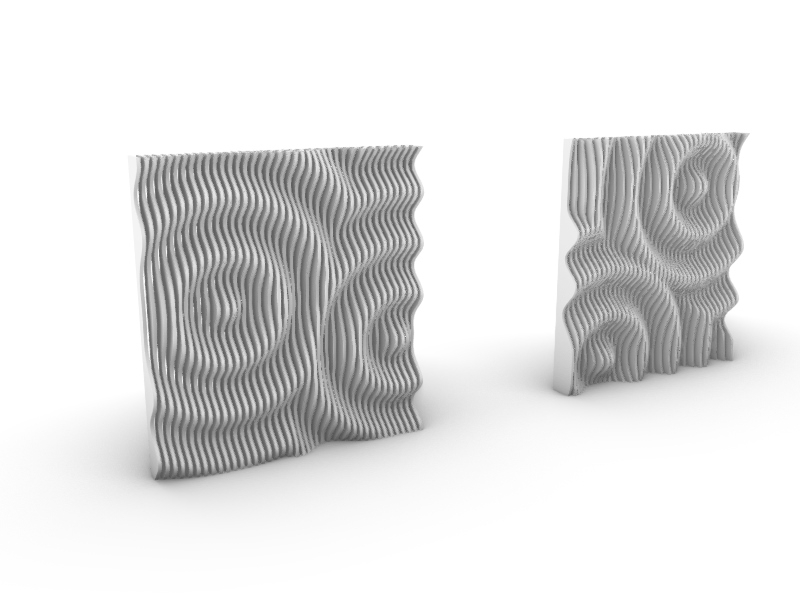

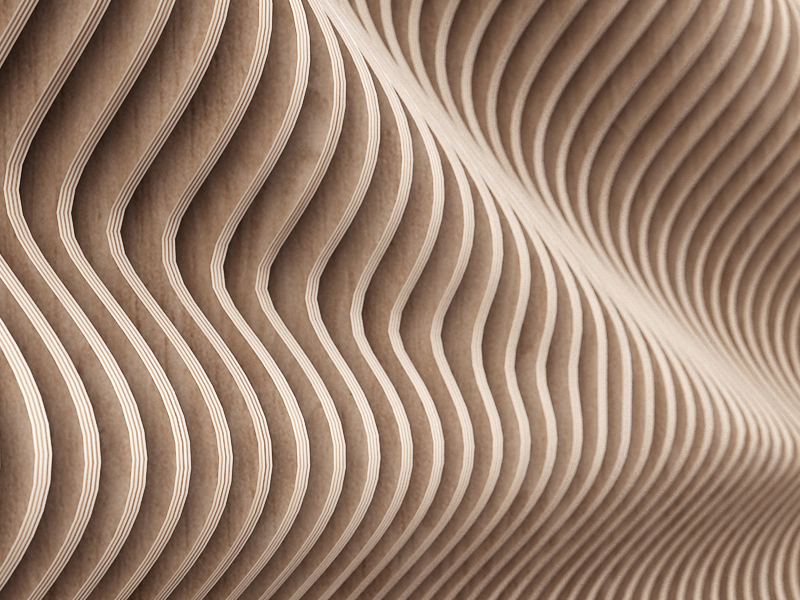

In the realm of parametric design and computational design, the web is full of rendered images and simulations showcasing fluid forms, non-standard repetitive elements, and innovative digital manufacturing techniques. However, many of these concepts remain unrealized, serving only as theoretical exercises. At Ergodomus, we took the challenge to transform this creativity into reality by designing and producing two parametric wall modules for our studio, combining art, engineering, and digital craftsmanship.

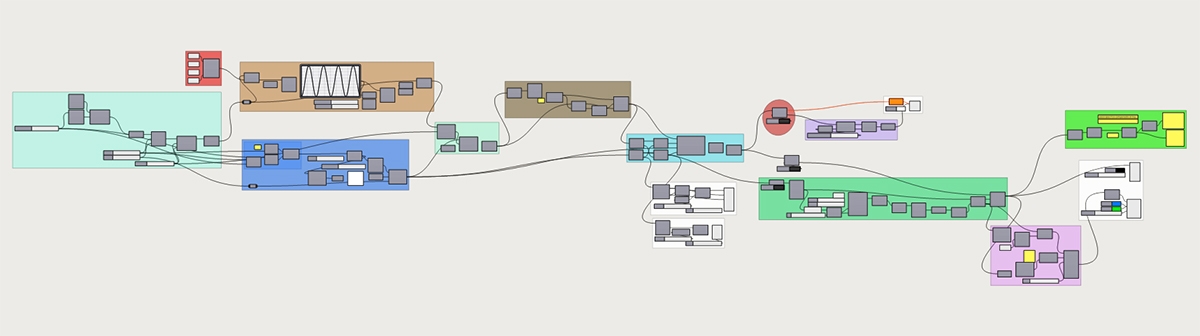

- STEP 1: Defining the Algorithm

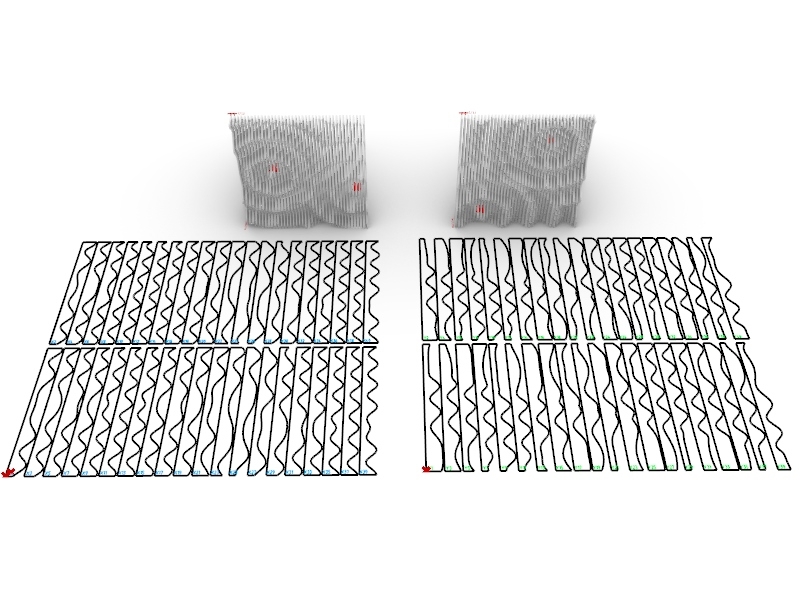

The process begins with defining the constraints and parameters, such as the installation dimensions, material type, thickness, and assembly method. The algorithmic modeling stage introduces variables to control the number of profiles, their shapes, and their arrangement. This iterative process allows real-time updates to the model, ensuring the final configuration meets both aesthetic and functional requirements. - STEP 2: Generating CNC Cutting Files

Once the design is finalized, an additional code layer extracts the 2D curves of the profiles, indexes them, and orients them on the XY plane for cutting. Any design modifications instantly update the cutting files, ensuring a seamless transition from 3D parametric model to production-ready data. - STEP 3: CNC Cutting and Installation

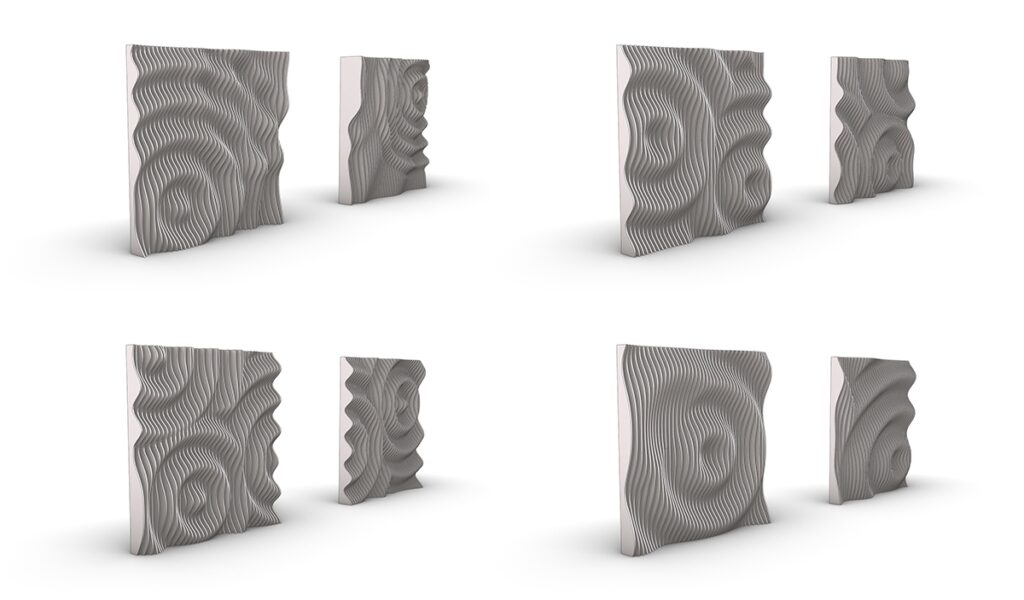

The final step is the CNC cutting of the profiles using 3-axis milling machines. This precision-driven process brings the design to life, creating elements that are perfectly aligned with the parametric intent. Once cut, the profiles are assembled into the final structure, showcasing how digital design meets physical craftsmanship.

Our Scope of Work

Here, you’ll find the engineering foundation behind this parametric wall. Take a journey through the technical efforts driving our designs.

By moving beyond simulation and into tangible results, this project highlights how computational design and digital manufacturing can be integrated to produce functional and artistic installations, pushing the boundaries of modern design and engineering.