What

Optimization does not always mean reducing the amount of material needed. Optimizing requires a careful analysis of the structure in all its aspects, comparing different solutions with each other and choosing the most effective taking into account the various phases, namely: production, transport and installation.

Optimizing means “weighing-up” all cost items and finding the right mix that makes the solution cost effective. Is it better to have less material or spend less time and resources on-site for assembly?

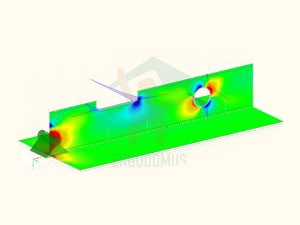

As a part of Design for Manaufature and Assembly (DfMA), Nesting is a process that can dramatically reduce the waste of material: to do this we use special ad-hoc algorithms that work on both timber and steel.

Why ?

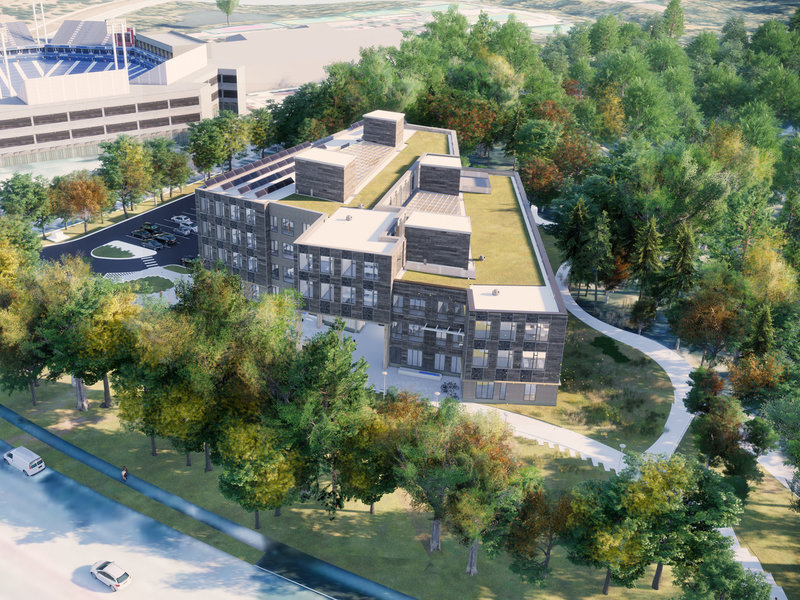

Have you ever thought about the labour time needed to place a single CLT panel? For example, reducing the number of pieces in an install will significantly reduce the costs in labour time. Likewise, choosing solutions that allow "top-down" appraoch reduce the number of "crane lifts" or the number of truck loads to the construction site. Value Engineering is one of the most delicate phases of the engineering process and it combines a true DfMA review with time and costs equations to deliver considerable benefits, all before you even start on-site.

Ergodomus has over 15 years of experience in the timber building sector and because of this, we can offer a 360 ° consulting service for Value Engineering based on varied cross-sector experiences: multi-storey, schools, residential, and commercial buildings.

Did you know that…?

The waste of material can account for more than 8-10% of the cost of the material. We can unlock savings by helping you reduce to less than 4%.

Contact us!

Sub services

QS

The Quantity Surveying departments of contractors/builders/developers do not always have sufficient knowledge of timber to make an accurate cost assessment. This often leads to an overestimation of costs, which ironically vetos this sustatinable option to use timber. Ergodomus offers a dedicated cost consulting service to support this QS function.

Building Codes

The international experience gained by Ergodomus allows us to offer a complete service even with different building regulations. We usually work with Eurocodes + Annexes but we have experience with numerous other calculation codes (Canada, USA, South Africa, etc...).

Computational Design

There are normally many potential solutions to compare, so we have to use a computational design approach by developing ad-hoc optimization algorithms. This is critical, as you cannot unlock efficiency by only comparing two or three options.

Read more